Kupfekedzwa kwemapombi

1, steam oxidation: pinda mumhepo yakakwira tembiricha yemvura, pamusoro pekuumbwa kweiyo oxide firimu, iyo inotonhorera adsorption yakanaka, inogona kuita basa mukuderedza kupokana, ichidzivirira tepi uye zvinhu zvekucheka pakati pechisungo, chakakodzera. yekugadzira simbi yakapfava.

2, nitriding kurapwa: tap pamusoro nitriding, kugadzira denga rinoomesa denga, rakakodzera kugadzirisa simbi yakakandwa, aluminium yakakandwa uye zvimwe zvinhu pazvipfeko zvekushandisa.

3, steam + nitriding: zvakanakira zvakanakira zviviri zviri pamusoro.

4, TiN: yegoridhe yero yekupotera, yakanaka kuomarara kuoma uye lubricity, uye coating adhesion performance yakanaka, yakakodzera kugadzirisa zvinhu zvakawanda.

5, TiCN: yebhuruu grey coating, kuomarara kunosvika 3000HV, kupisa kupisa kwe400°C.

6, TiN + TiCN: yakasviba yero yejasi, ine yakanakisa coating kuomarara uye lubricity, yakakodzera kugadzirisa akawanda ezvigadzirwa.

7, TiAlN: yebhuruu grey coating, kuoma 3300HV, kupisa kupisa kusvika ku900 ° C, inogona kushandiswa pakumhanya-mhanya.

8, CrN: sirivheri grey coating, lubrication performance iri pamusoro, inonyanya kushandiswa kugadzira simbi dzisina-ferrous.

Kuvharwa kwepombi kune chekuita kwakakura pakuita kwepombi, asi parizvino, vagadziri nevagadziri vematepi vanoshandirana mumwe nemumwe kudzidza yakakosha coating, senge LMT IQ, Walther THL, nezvimwe.

Zvinhu zvinokanganisa kubata

A. Tapping midziyo

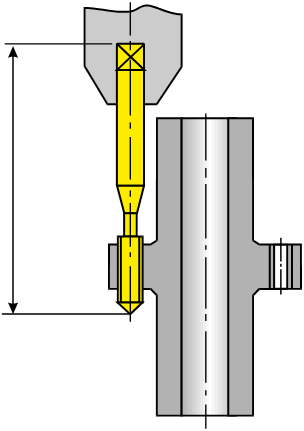

1. Machine tool: inogona kukamurwa kuva yakatwasuka uye yakatwasuka nzira dzekugadzirisa.Pakubata, kudzika kuri nani pane kugadzirisa kwakachinjika, uye kugadzirisa kwakatwasuka kunofanirwa kufunga kuti kutonhora kwakaringana here.

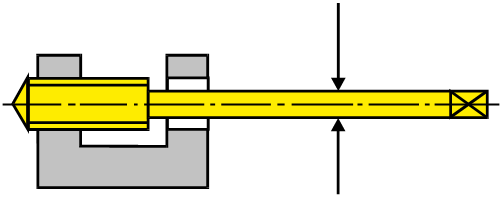

2, kubata shank: kubaya kunokurudzirwa kushandisa yakakosha tapping shank, kuomarara kwemuchina, kugadzikana kwakanaka kunosarudzwa kusarudza synchronous tapping shank, pane zvinopesana, sezvinobvira kusarudza flexible tapping shank ine axial / radial muripo.Shandisa square drive pese pazvinogoneka, kunze kwediki tap tap (

3. Mamiriro ekutonhodza: pakubata, kunyanya matepi eextrusion, chinodiwa chekutonhodza is lubrication > kutonhora;Mukushandiswa chaiko, inogona kugadzirirwa zvinoenderana nemamiriro emuchina chishandiso (kana uchishandisa emulsion, zvinokurudzirwa kuti iyo yekuisa yakakura kupfuura 10%).

B. Iyo workpiece inofanira kugadziriswa

1. Izvo zvinhu uye kuoma kweiyo yakagadzirwa workpiece: kuoma kwezvinhu zvekushanda kunofanira kuva yunifomu.Kazhinji hazvikurudzirwe kushandisa matepi kugadzirisa workpiece kupfuura HRC42.

2, kurovera pasi gomba: pasi pegomba chimiro, sarudza iyo chaiyo bhiti;Pazasi gomba dimensional kunyatsoita;Pazasi gomba madziro mashoma.

C. Processing parameters

1, kumhanya: kumhanya kunopiwa pahwaro hwemhando yepombi, zvinhu, zvakagadziridzwa zvinhu uye kuoma, zvakanakira uye zvakaipira zvekutepa michina.

Kazhinji inosarudzwa zvichienderana nemaparameter akapihwa nemugadziri wepombi, kumhanya kunofanirwa kudzikiswa pasi pemamiriro anotevera:

▶ muchina wekushandisa kuoma kwakashata;Kurova kwepombi yakakura;Kutonhora kusina kukwana;

▶ Kurovera nzvimbo kana kuoma hakuna yunifomu, senge majoini ekutengesa;

▶ Pombi inorebeswa, kana kuti tsvimbo yekuwedzera inoshandiswa;

▶ Supine, kunze kutonhora;

▶ Kushanda nemaoko, senge bhenji kudhiraivha, rocker drill, nezvimwe;

2, dyisa: kurovera kwakasimba, kudyisa = 1 pitch/turn.

Flexible tapping, uye shank muripo wekusiyana wakakwana:

Kudyisa = (0.95-0.98) pitch/revolution.

Mamwe matipi pakusarudza tap

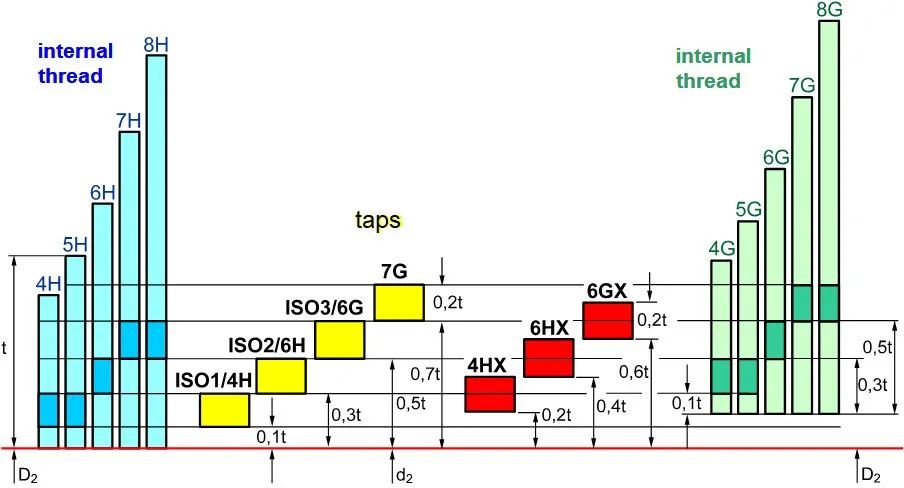

A. Kushivirira kwematepi emhando dzakasiyana dzemagiredhi

Sarudzo hwaro: kwete chete zvinoenderana negiredhi chaiyo yeshinda ichagadzirwa kusarudza uye kuona iyo chaiyo giredhi repombi.

▶ Izvo zvinhu uye kuoma kweiyo yakagadziriswa workpiece;

▶ Midziyo yekutepa (senge mamiriro emuchina, mubato wekusungirira, mhete yekutonhora, nezvimwewo);

▶ Iyo tepi pachayo iko kurongeka uye kukanganisa kwekugadzira.

Semuenzaniso: kugadzirisa 6H thread, mukugadzirwa kwesimbi, inogona kusarudza 6H chaiyo tap;Mukuita kwe grey cast iron, nekuti dhayamita yepakati yepombi inopfeka nekukurumidza, kuwedzera kwegomba rekupura idiki, saka zvakakodzera kusarudza 6HX chaiyo tap, hupenyu huchava nani.

Cherekedza nezve chokwadi chematepi echiJapan:

▶ Kucheka tapi OSG inoshandisa OH precision system.Yakasiyana kubva kuISO standard, OH precision system inomanikidza iyo yese kushivirira bhendi hupamhi kubva kune yakaderera muganho, yega yega 0.02mm seyero chaiyo, inonzi OH1, OH2, OH3, nezvimwe.

▶ Extrusion tap OSG inoshandisa RH precision system, RH chaiyo sisitimu inomanikidza kushivirira kwese kwese kubva pamuganho wakaderera, yega yega 0.0127mm seyero chaiyo, inonzi RH1, RH2, RH3 zvichingodaro.

Naizvozvo, kana uchitsiva OH precision tap neISO precision tap, 6H haifanirwe kutorwa seyakaenzana neOH3 kana OH4 level.Inofanira kugadziriswa nekutendeuka kana maererano nemamiriro chaiwo emutengi.

B. Dimension yekunze yepombi

1. Parizvino, inonyanya kushandiswa ndeyeDIN, ANSI, ISO, JIS, nezvimwewo.

2, zvinoenderana nezvinodiwa nemutengi zvakasiyana kana mamiriro aripo ekusarudza urefu hwakakodzera, kureba kweblade uye kubata sikweya saizi.

3. Kupindira panguva yekugadzirisa;

Tinya kusarudzwa kwezvinhu zvitanhatu zvakakosha

1, rudzi rwekugadzira tambo, metric, British, American, nezvimwewo;

2. Rudzi rweshinda pasi gomba, kuburikidza neburi kana bofu;

3, yakagadziriswa workpiece zvinhu uye kuoma;

4, workpiece yakazara shinda kudzika uye pasi gomba kudzika;

5, workpiece shinda chaiyo;

6, kutaridzika kweiyo tap standard (yakakosha zvinodikanwa zvinoda kumakwa).

Nguva yekutumira: Sep-22-2022